Solutions leading

to the future

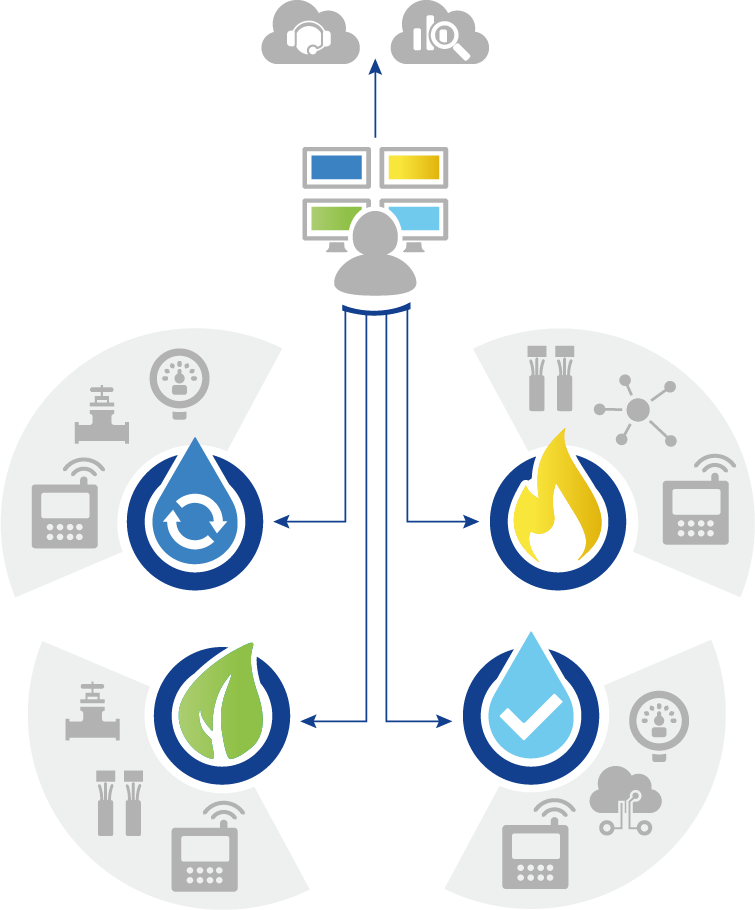

MONITORING AND CONTROL SYSTEMS IN WATER AND GAS NETWORKS

We build monitoring and control systems for companies that want to manage and optimize their plants, in the water and gas sectors.

Flexibility

Solutions designed with the customer through a continuous exchange of know-how to satisfy their needs.

Reliability

We use the best industrial components available to guarantee the certified quality of our projects, but also to leave the customer with full freedom of action.

Experience

The considerable know-how accumulated on a variety of cases allows us to see solutions where others see obstacles.

Continuity

We keep infrastructures updated by integrating new technologies, giving the customer the opportunity to make modular and targeted investments based on real data recorded by our equipment.

Field equipments

Essential equipment and technologies to connect and control processes, through acquisition, processing and data transmission systems. Not simple components, but solutions to manage the complexity of sites, plants and territories.

Control center, services and Cloud

Supervision and control, by means of data analysis and reporting, dynamic dashboards and KPIs, georeferencing and event analysis. Interoperability with other ICT systems, to enhance the value of all the information produced by remote control. Assistance and maintenance for efficiency and continuity of operation.

Field equipments

Essential equipment and technologies to connect and control processes, through acquisition, processing and data transmission systems. Not simple components, but solutions to manage the complexity of sites, plants and territories.

RTU

Know How, Automation

Control devices for data acquisition, processing, storage and transmission. Distributed automation, command security, local user interface. Standard protocols and industrial components.

IoT

Smart, Wireless

Battery-powered devices and sensors, cloud connected. Communication on NB-IoT and LoRaWAN networks. Integration via pull/push API. Integration with hydraulic equipment.

COMMUNICATION NETWORKS

Performance, Efficiency

Design and development of the optimal solution. Wired, wireless, openness, interoperability. State of the art and continuity of service.

CABINET & CABLING

Engineering, Safety

Electrical infrastructure for supply, command and connection between the process’ instrumentations and the control system. Installation’s Safety and functionality.

INSTRUMENTATIONS

Technology, Precision

Detection of physical, chemical, electric and environmental data. Selection and sizing accordingly to the specifics of the process being monitored. Installation and interfacing with the control system.

ACTUATORS

Reliability, Strength

Control of hydraulic and mechanical equipment. Integration with shut-off and regulation valves. Customization and fine-tuning.

Control center, services and Cloud

Supervision and control, by means of data analysis and reporting, dynamic dashboards and KPIs, georeferencing and event analysis. Interoperability with other ICT systems, to enhance the value of all the information produced by remote control. Assistance and maintenance for efficiency and continuity of operation.

Scada control center

Monitoring, Control

SCADA applications for effective process control. Ergonomic HMIs, centralized automation, event analysis and notification. Control room and ICT integration.

Cloud services

Scalability, Interoperability

Simple and intuitive access to process data, via web interface. Smart UX, analytics, KPI, geolocation, data extraction. Sharing of information, APP and mobile device support.

Support & Maintenance

Support, Continuity

Technical support and on-call services to ensure the maximum operational continuity of our systems. Preventive and corrective maintenance. Help-desk, assistance both remote and on-site.

We create value from data

COST REDUCTION

Annual savings of 40% to 70% through process control, automation and data analysis.

ENERGETIC EFFICIENCY

Control and reduction of consumption, energy optimization of plants.

WATER SAVING

Reduction of Non-Revenue Water (NRW). Active pressure control, leakage monitoring.

ASSET CONTROL

Historical process data analysis, KPIs, statistics, time comparisons. Simplification and growth.

MANAGEMENT OPTIMISATION

Support to the activities of conduction, ordinary and extraordinary maintenance

Operational safety

Visualization and forwarding of alarms in real time. Management of the fields interventions.

MONITORING

Real-time visualization of status and process measurements.

CONTROL

Interaction with the processes operating parameters.

AUTOMATION

Automatic adjustment of processes operating parameters.